The Delta K Avalanche Control Programme

In 1999 Delta K conducted a series of research studies with the support of The Center for Snow Science at Alta (CSSA) in Utah, USA and the Avalanche Artillery Users of North America Committee (AAUNAC). Following a successful demonstration of the use of a specialised reactive shaped charge design for stimulating artificial avalanche release, plans were made to fund a broader programme of study to review and assess the current use of explosives for avalanche control and identify areas of application of advanced explosives technologies. This led to a contract for a three year programme jointly funded by the AAUNAC members, the CSSA and three US Departments of Transportation.

Avalanche control programmes are intended to mitigate the threat of damage caused by avalanche run-outs through: management of natural stabilisation features; introduction of permanent stabilizing structures; construction of physical barriers to protect key assets and continuous artificial stimulation of controlled releases by blast, shock and vibration primarily generated by energetic materials.

Delta K’s contribution to these mitigation programmes is associated with the optimisation of explosive effects intended to stimulate artificial avalanche release. Whilst the methods and techniques adopted in avalanche control programmes vary considerably depending on geographic location, accessibility, local topography, and prevailing weather conditions, the need to conduct active control work is based on local experience underpinned by a continuous interactive process of regional and local weather monitoring conducted throughout the avalanche season. The methods and techniques employed in these control activities can be grouped under the following generic headings.

Hand Charge Operations

For Hand Charge Operations, piste patrollers ski or hike to positions above known "start zones" and then ski established descending routes, ski cutting and/or placing and detonating charges as they go. Charges are typically standard 1kg or 2kg Pentolite boosters as shown to the left. These are detonated by capped Safety Fuze, typically with a 90s delay (about 750mm in length) The fuze is ignited by a standard Pull Wire Igniter, also shown in the photograph. Although, where practicable, charges can be cast directly into the start zone, the optimum effect is achieved by elevating the charge to a height of about 1.5m. This is often achieved by taping the charge to a bamboo pole. Note, for illustration purposes, the photograph shows a very short length of fuze.

Artillery Operations

Typically, artillery operations include the use of 105mm Pack Howitzers, 75mm and 106mm Recoilless Rifles and other military gun systems. These provide long range capability but the disadvantage is maintenance cost, specialist training, risk of overshoot and the fragmentation hazard associated with HE rounds. The 106mm recoilless rifle, at Alta in Utah, shown to the left has a lower range and maintenance requirement, but ammunition is both old and scarce. Shorter range requirements (less than 2km) are met with compressed gas launchers (Avalaunchers), and other fixed remotely operated mortar type launcher systems such as the Avalanche Guard. High performance gas launchers, such as the LoCAT and AVCONS systems with range capabilities up to 5km also exist. Delta K has designed and developed commercial ammunition for the Avalauncher and LoCAT launcher systems.

Work on the DeltaLancer ammunition for the high performance launchers has paved the way for long range (5km) ammunition together with the more complex considerations for 105mm and 106mm replacement ammunition. The underlying problem with heavily cased military ammunition is that the Bare Charge Equivalent (BCE) of a 15kg shell carrying 2.5kg is actually less than 1kg of HE and this probably detonates after partial penetration of the base scree. Delta K studies have, therefore, concentrated on determining if advanced gas launchers could be a more cost effective overall solution to Artillery ammunition.

Aerial Operations

Helibombing is the most flexible and effective option involving strategic drops of 1kg and 2kg high explosive booster charges and larger 25 to 50kg packs of commercial blasting explosive. Such operations are weather dependent but are often the only method of getting above remote slide paths. There are also a number of permanent wire traverse systems that enable suspended charges to be traversed to the optimum position before a delay fuze detonates the charge, these can be further optimized by lowering the charge to the optimum height above the snow pack. The Wyssen Avalanche Tower consists of a fixed tower onto which a carousel carrying numerous charges can be mounted by helicopter. The charges can then be dropped remotely to the optimum height where they detonate after a short delay. The Daisy Bell, a variant of the Gaz-Ex blast wave generator below, is designed to be suspended below a helicopter and fired from the cockpit.

Fixed Propane Blast Generators

In remote areas charges can be pre-positioned at the start of the season and fired remotely, however the charges are susceptible to damage by slides and/or incremental snow pack weight, the charges also need to be many kilos and are difficult to manage from a security perspective. Relatively low pressure wide area pulses can be generated by fixed installations that ignite and direct explosive gas mixtures. Gaz-Ex (shown left) is an established commercial example in which a Propane/Oxygen mixture is injected into the combustion chamber and ignited by remote control. The pipe guides the pressure pulse that exits and propagates across the start zone triggering any prevalent instabilities. This installation shown left is located at Teton Pass in the USA.

Areas of focus arising from the DoT and AAUNAC funded review of explosives applications included implementation of reactive shaped charge technology, improvements to gas launcher range and ammunition effectiveness and the replacement of military 105mm and 106mm ammunition with designs optimised for avalanche control applications.

Early shaped charge studies at Alta demonstrated a significant 5 fold increase in snow pack crater volume, together with other benefits related to the highly directional nature of the shock and blast effects radiating from the reactive penetrating jet. As these effects could be exploited readily in Hand Charge and Aerial Operations, Delta K concentrated on improving the range and terminal effectiveness of Avalauncher ammunition. Delta K's DeltaLancer carrier vehicle technology was adapted to meet the broad operational requirements of Hand Charge, Artillery, and Aerial avalanche control operations. Three basic charge configurations arose from these early studies and these are described in the following section.

DeltaLancer Variants for Avalanche Control

The broad objective of this development programme was to exploit the inherent modularity of Delta K’s DeltaLancer carrier vehicle technology to produce a common blast or shaped charge assisted explosive payload to which appropriate safe arming and fuzing options could be fitted to meet the broad requirements of Hand Charge, Gas Gun and Aerial avalanche control operations.

DeltaLancer Hand Charge (HC)

The photograph shows an example of the DeltaLancer Hand Charge (HC) charge configuration. The common Forebody moulding (Red) can be loaded with a cast explosive, deformable commercial gel, plastic explosive or liquid explosive in a sealed insert - with or without the shaped charge liner. In this particular case a canister containing spooled shock tube is shown located coaxially over the Fin body (with the fin vanes removed). The two loops can be hooked into a carabina whilst the operator is casting the charge. This provides a means of tethering and controlling the charge position before firing and also provides a means of recovering the charge in the event of a dud or vetoed shot. The Shock Tube can be initiated with an electronic firing pack or 209 shot shell primer initiator.

Note the Forebody assembly is common to all three variants.

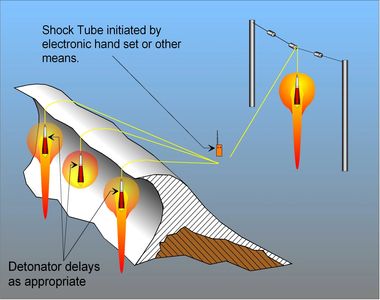

Charge Suspension Using Shock Tube

The illustration shows examples of how the shock tube tether and fire control system can be used to suspend a charge or charge array with or without shaped charge effects. Standard delay detonators can be used to set up a travelling shock front along the face of the cornice.

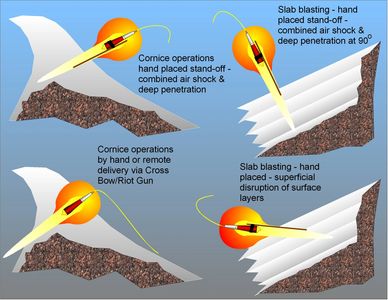

Shaped Charge Applications

The illustration indicates how the directional effects of the shaped charge option can be exploited for Bamboo shots (above and below to the right). Cornice formations, (above and below to the left), often need careful management and the unique ability of the shaped charge to fracture the ice at the base of the formation, following shaped charge penetration from the back, has been demonstrated at Alta.

DeltaLancer Gas Gun (GG)

The DeltaLancer gas gun projectile is shown sectioned with the optional shaped charge embodied within the Forebody moulding and optional self-clearance delay fuze fitted in the Multi-function nose cone. The projectile is forward obturated by a plastic piston ring located behind the parallel section of the Forebody.

Forward obturation is a fundamental departure from past base-pushed ammunition designs and is necessary to ensure that the increased axial forces exerted by higher firing pressures associated with new Avalauncher designs can be properly dissipated and to reduce the shock loading on the fuze components and detonator.

Standard Fin Assembly

The standard Fin Assembly has a turbine activated Safe Arming Mechanism and inertial fuze mechanism that can accommodate a Blasting Cap (pyrotechnic detonator cap) or an instant shock tube type Non Primary Explosive Detonator (NPED).

Nose Cone Inertial Fuze Options

The nose cone can be fitted with an inertial impact fuze or self-clearance fuze. If the inertial impact fuze is fitted in the nose cone, the self-clearance fuze components can be transferred to the Fin Assembly.

ADD NACELLE FUZE VARIENTS

Payload Increased Mass Options

The standard round is loaded with 1kg of explosive but can accommodate up to 1.2kg. The parallel section of the Forebody moulding can, however, be extended to accommodate a further increase in the payload. The nose cone can be fitted with an instant inertial fuze if required, and under these circumstances, the self-clearance fuze components can be transferred from the nose cone to the Fin Assembly.

Latest Upgrade For Extended Range Capability

Delta K's Fin and nose cone inertial fuze options can be replaced with a standard mortar fuze by replacing the Joint Ferrule and nose cone mouldings with a new adaptor. Whilst this configuration was primarily designed to provide replacement ammunition for the 80mm calibre LoCAT and AVCONS launchers, the adaptor can, nevertheless, be fitted to standard DeltaLancer Forebodies; as shown above. This improves safety and handling significantly and facilitates safe firing of Falcon and Nitro Xpress launchers at pressures in excess of 300psi.

Maximum Range Potential For Avalauncher Ammunition

The maximum range achievable with the DeltaLancer ammunition is governed by a complex interaction between projectile strength of design, projectile aerodynamics and the launcher’s design and performance parameters. For compressed gas launchers, the optimum range achievable with mortar type “fin stabilised” projectiles, is constrained by aerodynamic drag considerations, primarily because aerodynamic drag increases rapidly above and around Mach 0.85 (280m/s @ MSL).

Given this 280m/s constraint and a typical drag coefficient of 0.15 at Mach 0.85, for DeltaLancer, mass becomes the key parameter affecting the maximum range potential, provided the launcher can achieve a 280m/s muzzle velocity. By way of example: for a launch velocity of 280m/s (MSL) and quadrant elevation of 41 degrees, the “modelled” range for a 1, 2, 3, and 4kg projectile would be, 2.4km, 3.6km, 4.3km, and 4.8km respectively. This, however, assumes the launcher is indeed capable of driving the mass, in each case, to 280m/s - and the projectile stays in one piece.

Considering the DeltaLancer projectile, with a 1kg payload, the maximum practicable range for a muzzle velocity of 280m/s would be 2.9km. This, however, is of academic interest with respect to current Avalauncher designs as the maximum firing pressure for the latest variants is probably around 600psi. For the Nitro Xpress launcher the “modelled” muzzle velocity, for a 1.29kg DeltaLancer round, would be about 250m/s, so the maximum range potential for DeltaLancer could be about 2.6km. This is realistic as the DeltaLancer GG ammunition has already been fired at 600psi, albeit from Delta K’s launcher with a smaller pressure chamber and shorter barrel.

Ongoing development work on a replacement round for the LoCAT and AVCONS launcher system is studying a ruggedised DeltaLancer based ammunition with a standard mortar fuze interface.

LoCAT DeltaLancer Based Mid-range Ammunition

For a 1kg payload and mortar fuze, this DeltaLancer based, all plastic, round has a launch mass of 1.65kg. It is anticipated that a muzzle velocity of 280m/s could be achieved for a firing pressure of between 1,000psi to 1,500psi. This could achieve a “modelled” range of about 3.3km.

LoCAT Replacement Long Range Ammunition

A replacement aluminium projectile for LoCAT, capable of being fired at the full operating pressure of 3,000psi, has also been designed that increases the original 0.53kg payload to about 1.5kg. Firing trials should start in March/April 2018.

DeltaLancer Helibombing (HB)

The photograph shows a DeltaLancer Fin and Forebody assembly with an extended turbine rotor (black) clipped over the standard Fin turbine (red). For the Helibombing variant, the inertial striker has been replaced by a spring loaded striker that ignites a delayed detonation train when the Turbine assembly separates from the Fin.

The safety Transit Strap is still fitted but this is backed up by an additional Ring Pull slip-pin that should be drawn immediately before the charge is released. Although the Fin can be transported with the detonator fitted, the latest "fin-lock" joint enables the option to fit the detonator cap whilst approaching the drop zone.

After release, the striker is drawn back against the spring by airflow through the rotor blades. When the turbine spins free of Fin, at about 15m below the Helicopter, the striker ignites a delay train that gives time for the charge to drop into the snow pack and the Helicopter to fly clear of the drop location. Besides eliminating the pervasive reek of burning Safety Fuze in the cockpit, this system also eliminates the risks associated with igniting explosive charge fuzes within the cockpit.

REPLACE PHOTO WITH LATEST BUILD STANDARD

Use of Commercial Blasting Explosive

The photograph shows an alternative option that enables standard commercial gel cartridges to be used with the Helibombing Fin. In this case either a complete empty Forebody, or the stub Forebody shown, can be used to support the donor charge around which any number of additional cartridges can be taped. To some extent, the charge mass will be limited by the necessity to ensure free air flow past the arming rotor blades. However, it is feasible to separate the fin and charge with an extended length of Safety Fuze, so it may be practicable to use the free fall igniter system with larger ANFO packs.

Aerial Delivery of Shaped Charge Effects

The illustration indicates how the gun launched shaped charge option can be effective in both proximity and impact detonation modes. In the proximity mode the jet ablates in the atmosphere producing a unique highly directional shock and blast field. In the impact mode the jet generates a deep penetrating shock and blast field in the snow pack. In both cases these energetic shaped charge effects are additional to the normal shock and blast yield associated with the explosive charge alone.

REMOVE PROXIMITY FROM ARTWORK

Copyright © 2018 Delta K EES Ltd. - All Rights Reserved.